View attachment 22069 ive built the 4-stroke cdi as in the diagram and it works . ive takan apart the old cdi to find a bad diode. replaced it and it works again. but i noticed an extra cap and resistor, sort of buffering the charge voltage, and the trigger signal input resistors are different. unreadable triac so i removed it and compared it resistively to my new triac. interesting that resistance from trigger to cathode on new was like 70 ohm and the old one was about 25 ohm. thise differences leave me to think tthe triacs might have different trigger requirements.matched by different resistors. if so itll change the dwell time. si im hoping someone can help to figure out the triac chip. ive yet to find another 2 stroke cdi diagram on the net, its like the last piece of the puzzle. ill try to post a list of the available triacs too.....the easy thing to know is the voltage and the amperage is 400v 4A or higher, the turn on time seems almost a non issue because they are intended to operate at extremely high frequencies, but does the turn on time vary slightly with signal power. seems that within the 400v 4A variety, theres ones with different triger sensitivities- wattage and voltage as well as the reaction time(turn on time). so these differences i believe interact with how the trigger signal amplitude would increase with rpm to acheive an advance curve.im just a guessing that by the 2 stroke diagram showing the lower resistance for trigger signal to ground, draining more signal power, theres less power to trigger and so the 2 stroke must trigger at less voltage-power, thus the chip would internally have less resistance, so for less can still get through and activate. i should just put my old one back on and compare. but it would be nice to figure it out while im on the subject, id like to know for future if i ever need to change the chip. all this is inside the black sem cdi coil box. wine was marked sem amal x1 or 1x . i chipped at the plastic to find out the pc board was on the bottom on the flattest surface i gouged my way through just below the 2 bolt holes, right where the wires come out beside one bolt hole. about 1 cm below the bolt holes. so now the cdi and coil are separate joined by two wires. never did get to the big capacitor , its buried up along side the coil. the scr triac chips are only dollars each and so i might just get an assortment and measure each one to get one with similar resistances then try that one in the homemade to see if itll work as the 2 stroke schematic. it seems the triac series in the 4 stroke diagram works rather well but wont fire in the 2 stroke diagram i traced, leading me to question the triac internal resistance and trigger specs. if we could figure this out , we could build a cdi and affix it tothe old coilpack, after cutting the old one. make it rpairable

View attachment 22069 ive built the 4-stroke cdi as in the diagram and it works . ive takan apart the old cdi to find a bad diode. replaced it and it works again. but i noticed an extra cap and resistor, sort of buffering the charge voltage, and the trigger signal input resistors are different. unreadable triac so i removed it and compared it resistively to my new triac. interesting that resistance from trigger to cathode on new was like 70 ohm and the old one was about 25 ohm. thise differences leave me to think tthe triacs might have different trigger requirements.matched by different resistors. if so itll change the dwell time. si im hoping someone can help to figure out the triac chip. ive yet to find another 2 stroke cdi diagram on the net, its like the last piece of the puzzle. ill try to post a list of the available triacs too.....the easy thing to know is the voltage and the amperage is 400v 4A or higher, the turn on time seems almost a non issue because they are intended to operate at extremely high frequencies, but does the turn on time vary slightly with signal power. seems that within the 400v 4A variety, theres ones with different triger sensitivities- wattage and voltage as well as the reaction time(turn on time). so these differences i believe interact with how the trigger signal amplitude would increase with rpm to acheive an advance curve.im just a guessing that by the 2 stroke diagram showing the lower resistance for trigger signal to ground, draining more signal power, theres less power to trigger and so the 2 stroke must trigger at less voltage-power, thus the chip would internally have less resistance, so for less can still get through and activate. i should just put my old one back on and compare. but it would be nice to figure it out while im on the subject, id like to know for future if i ever need to change the chip. all this is inside the black sem cdi coil box. wine was marked sem amal x1 or 1x . i chipped at the plastic to find out the pc board was on the bottom on the flattest surface i gouged my way through just below the 2 bolt holes, right where the wires come out beside one bolt hole. about 1 cm below the bolt holes. so now the cdi and coil are separate joined by two wires. never did get to the big capacitor , its buried up along side the coil. the scr triac chips are only dollars each and so i might just get an assortment and measure each one to get one with similar resistances then try that one in the homemade to see if itll work as the 2 stroke schematic. it seems the triac series in the 4 stroke diagram works rather well but wont fire in the 2 stroke diagram i traced, leading me to question the triac internal resistance and trigger specs. if we could figure this out , we could build a cdi and affix it tothe old coilpack, after cutting the old one. make it rpairable

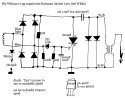

first pic is the two schematics, one is 4st from ktm 400 with sem, second is 2st off 84 husky wr 240, marked by X1 or 1X on bottom, now removed. you can see the numbers that got imprinted onto the potting glue, and cant read them nomore, also a dabble of solder to join the capacitor and coil leads, and that its now joined by two wires to cdi.