hawaii-rider

Husqvarna

AA Class

Ten Fins has her wings!

Well.....I was messing with jetting on my Miss Ten Fins and her 40mm carb.

In search of cleaning response up a bunch and searching for a bit more punch off the bottom and transition into mid without replacing the 40 for a 38mm as I have read was the hot ticket.

so.......HR begins thinking...(dangerous mind you)

I have had incredible success and results out of intake blades.

I have fab'd a whole bunch of my own and purchased them as well.

so.....what did I have to loose, about a tiny tiny piece of $5.00 of .025" sheet aluminum and some time.

so I sketched and mic'd out a full up intake bell unit and after working through how to stabilize it in the carb I went to the two blade cross design.

I had a contour guage so I copied everything over for both vert and horizontal and went to work.

fit perfect, extra tabs to secure it to the bell.

Jetting, I went back to stock settings, pure stock.

there was a 310 main in ol Ten Fins, I went to a 340

Stock needle at the 3rd clip

Stock needle jet

Pilot WAS at a 40, bumped it up to a 45.

Had a race last weekend....

OMG what a transformation in power!

she is just as smooth from bottom to top but has wonderful punch and snap off the bottom now where before she was super soft until you got things rolling.

I could now run her 2 gears up and just almost lug it.

I holeshot the 2nd moto, and one of the guys I was racing with said that after the first turn I simply checked out.

Bike ran simply incredibly well and for me, a huge improvement in power, snap, throttle response from mid to very very low.

Cost, oh if I figure how much of the sheet of alum I used (not counting my therapy time in the garage) about $.24

here are some shots.

Pieces before fitting

the "ring" piece keeps the blades from moving.

only thing I had not done to the two blades was 1/2 notch at center to side them together

Here is the mounting ring

there are three tabs that you can see here, those are what I used to secure the Ten Fins Wings of Fury to the carb, they simply roll over. No glue or anything holding the intake blades to the carb, tight fit + the tabs

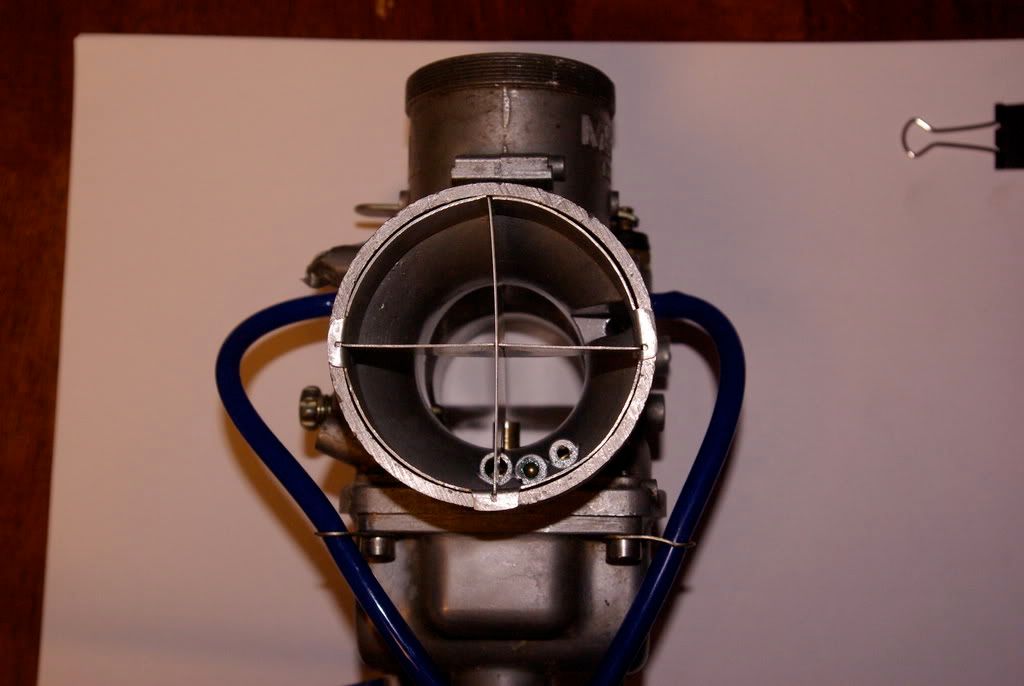

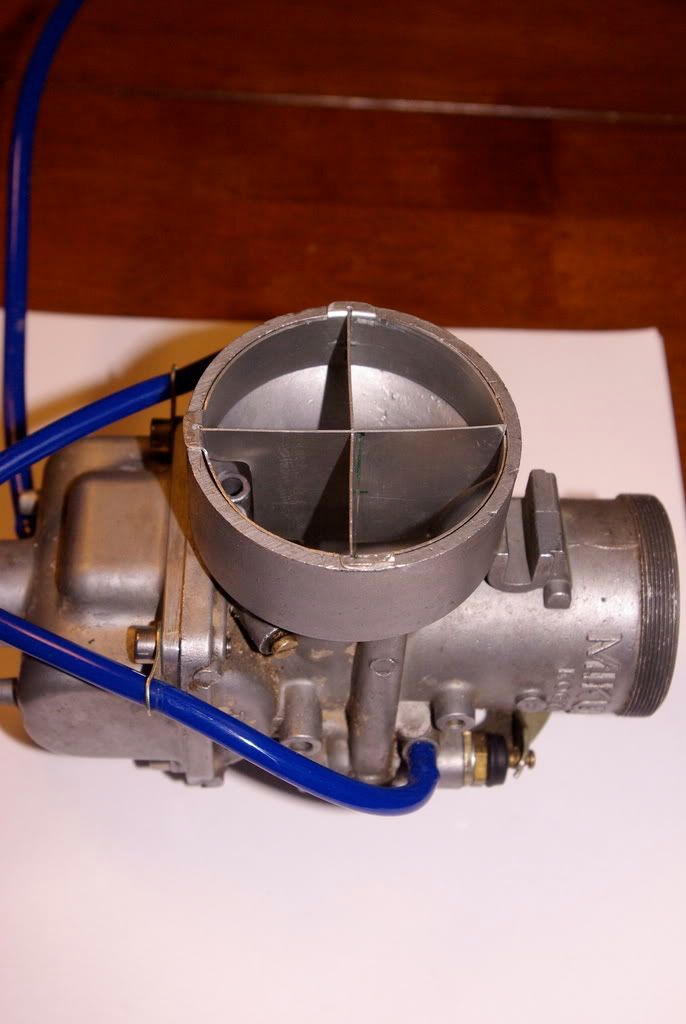

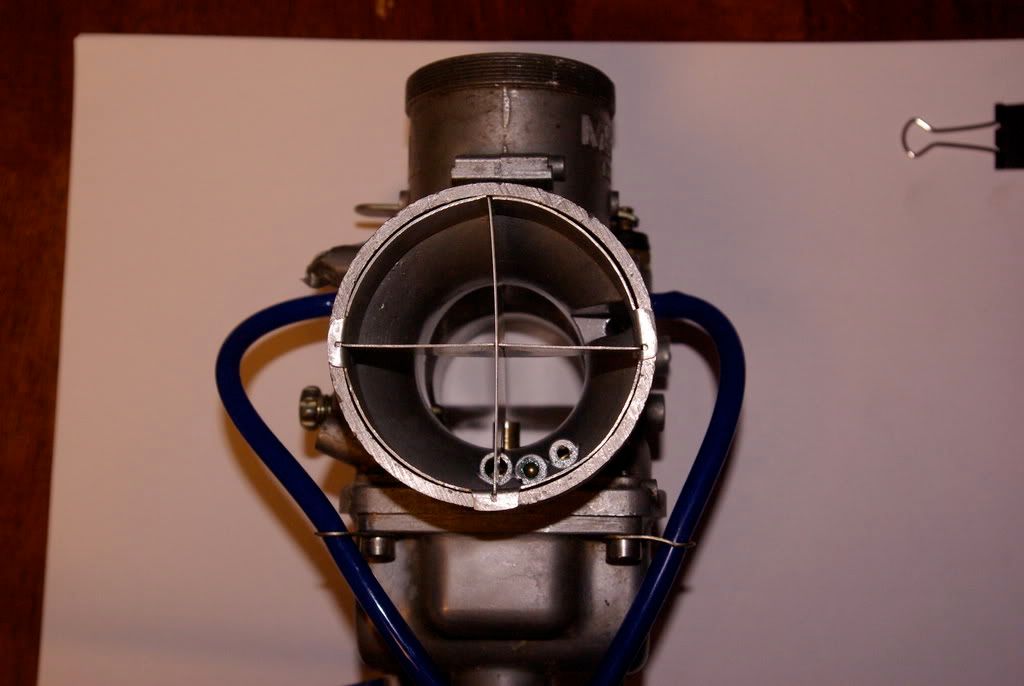

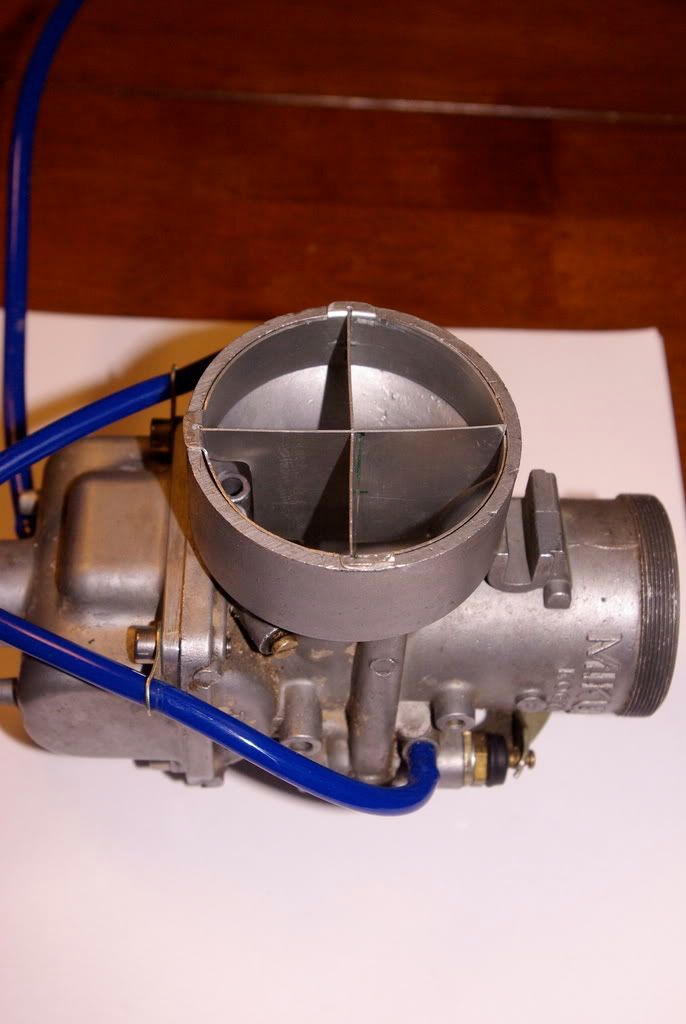

Here are two shots of everything together

It isnt sell it pretty, but its solid, and most importantly it works!!!

Hand tools only, dont have anything fancy.

HR

:usa:

Well.....I was messing with jetting on my Miss Ten Fins and her 40mm carb.

In search of cleaning response up a bunch and searching for a bit more punch off the bottom and transition into mid without replacing the 40 for a 38mm as I have read was the hot ticket.

so.......HR begins thinking...(dangerous mind you)

I have had incredible success and results out of intake blades.

I have fab'd a whole bunch of my own and purchased them as well.

so.....what did I have to loose, about a tiny tiny piece of $5.00 of .025" sheet aluminum and some time.

so I sketched and mic'd out a full up intake bell unit and after working through how to stabilize it in the carb I went to the two blade cross design.

I had a contour guage so I copied everything over for both vert and horizontal and went to work.

fit perfect, extra tabs to secure it to the bell.

Jetting, I went back to stock settings, pure stock.

there was a 310 main in ol Ten Fins, I went to a 340

Stock needle at the 3rd clip

Stock needle jet

Pilot WAS at a 40, bumped it up to a 45.

Had a race last weekend....

OMG what a transformation in power!

she is just as smooth from bottom to top but has wonderful punch and snap off the bottom now where before she was super soft until you got things rolling.

I could now run her 2 gears up and just almost lug it.

I holeshot the 2nd moto, and one of the guys I was racing with said that after the first turn I simply checked out.

Bike ran simply incredibly well and for me, a huge improvement in power, snap, throttle response from mid to very very low.

Cost, oh if I figure how much of the sheet of alum I used (not counting my therapy time in the garage) about $.24

here are some shots.

Pieces before fitting

the "ring" piece keeps the blades from moving.

only thing I had not done to the two blades was 1/2 notch at center to side them together

Here is the mounting ring

there are three tabs that you can see here, those are what I used to secure the Ten Fins Wings of Fury to the carb, they simply roll over. No glue or anything holding the intake blades to the carb, tight fit + the tabs

Here are two shots of everything together

It isnt sell it pretty, but its solid, and most importantly it works!!!

Hand tools only, dont have anything fancy.

HR

:usa: