DON't use a heat gun!!

A half-decent hairdryer is powerful enough to do the job. The heatgun will be hot enough to shrink your material to 1/4 to 1/20th of it's original size, also rendering it brittle and useless. It's usually HDPE (high density Poly-ethylene) and a thermoplastic for the start. the super-thin-wall stuff will shrink within fractions of a second if past the critical ~250F.

http://en.wikipedia.org/wiki/High-density_polyethylene

Rather try an old engine-oil container, many of them are stamped PP on the bottom somewhere.

Poly-propylene is far more temperature stable and morphs way slower from rigid-to-pliable/ re-shapeable when heat is applied. It's also thicker...and machinable.

http://en.wikipedia.org/wiki/Plastic_bottle

With all heat-mouldable materials, have a wet or damp (cold water) soaked rag handy to "set" the remoulded shape quickly to create a new "memory"-setting.

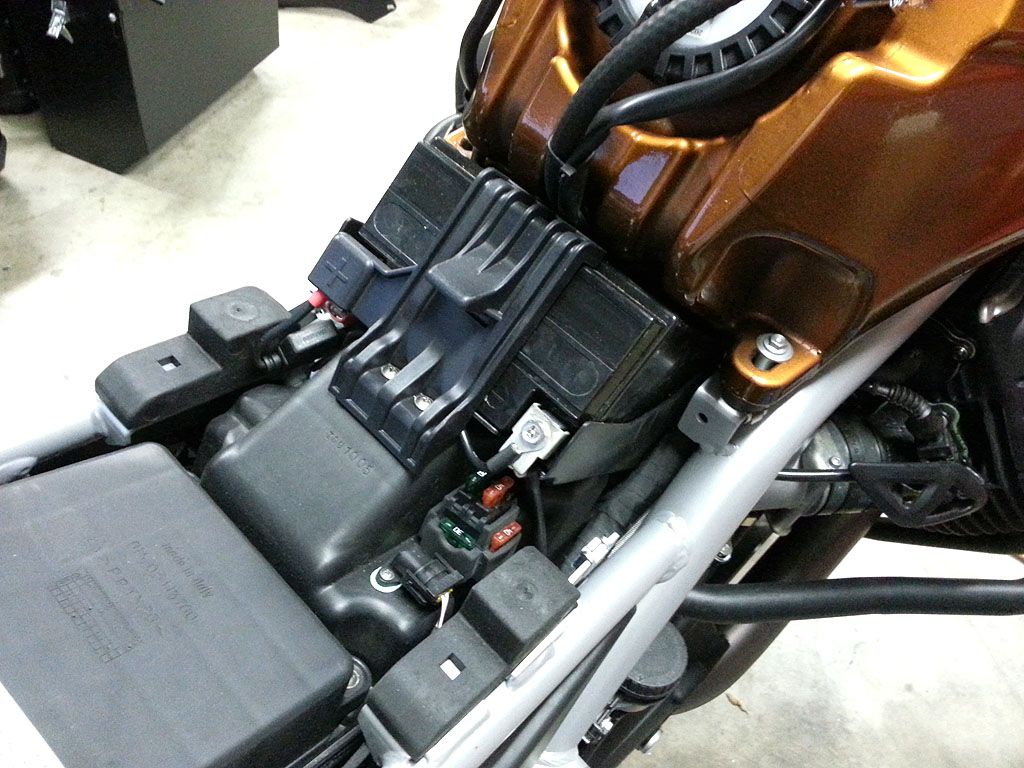

Yes, I play with this stuff every day...and pls DISCONNECT that ECU before playing around with it

Thinking about it....I could take out my ECU, make a plaster-master-copy and and make the covers out of 0.8-1.2mm PP sheeting in my vacuum-moulder at work. If it's worth the effort?

I found out the hard way..lol Back to the drawing board. I will borrow the hair dryer this time.

I found out the hard way..lol Back to the drawing board. I will borrow the hair dryer this time. I found out the hard way..lol Back to the drawing board. I will borrow the hair dryer this time.

I found out the hard way..lol Back to the drawing board. I will borrow the hair dryer this time.