I should mention this. The reason to stay away from batteries with bms in a real dirt or dual sport application.

If the battery is just on the verge of being able to start the bike. Lets say 9-10v for lead acid. A comparable lithium battery with bms will not truy to start.....at all! You will likely be stranded. A good chance of this happening if you leave the key on or use a electric acessory which runs the lith. Battery down it will simply do nothing. Lead acid may very well crank the bike over and get you started.

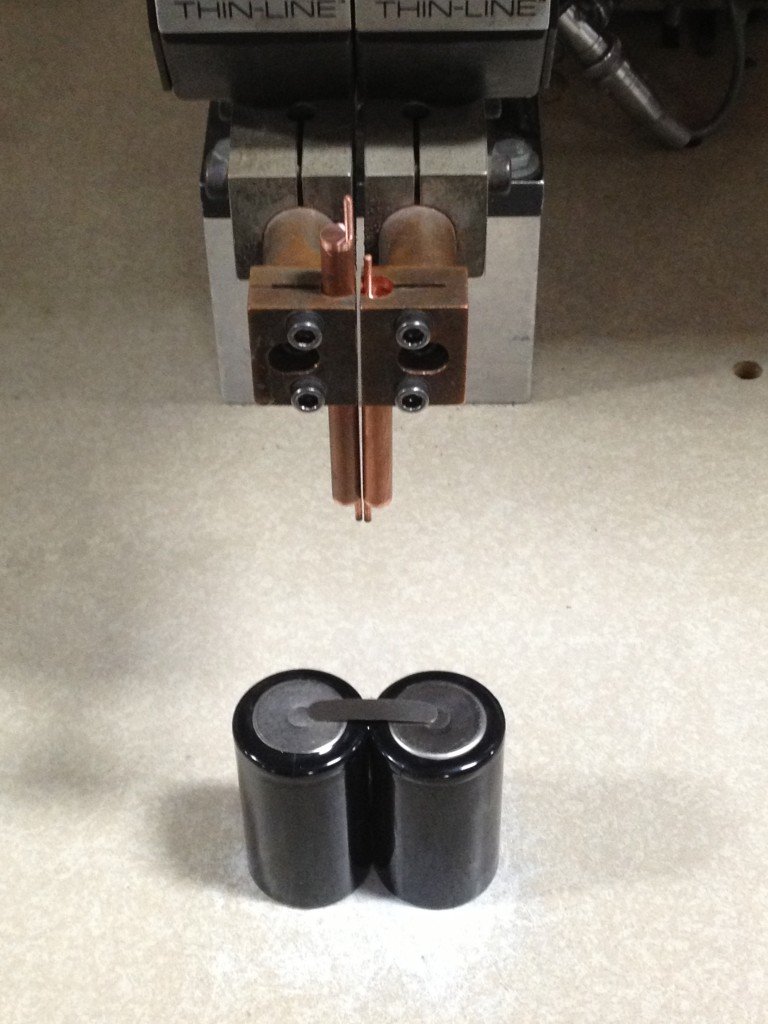

I build many lithium batteries for my bikes. Http://www.pacificebike.com that said when around town commuting I use lithium. On a long trip far from home where I need reliability, believe it or not I throw a new lead acid in. I have been stranded by several s based powersports batteries in the past. Now I build my own sonic welded packs with a123 cells. These have no bms and will simply damage themselves before they would not supply the amperage. The downside is any problem with the stator or short in wiring can be VERY bad. Overcharging lithium cells can cause them to burst and vent all kinds of horrible sometimes flammable substances. Ever see a lithium battery burn?

I am a huge advocate of lithium batteries but not in a powersports application.

My $0.02

If the battery is just on the verge of being able to start the bike. Lets say 9-10v for lead acid. A comparable lithium battery with bms will not truy to start.....at all! You will likely be stranded. A good chance of this happening if you leave the key on or use a electric acessory which runs the lith. Battery down it will simply do nothing. Lead acid may very well crank the bike over and get you started.

I build many lithium batteries for my bikes. Http://www.pacificebike.com that said when around town commuting I use lithium. On a long trip far from home where I need reliability, believe it or not I throw a new lead acid in. I have been stranded by several s based powersports batteries in the past. Now I build my own sonic welded packs with a123 cells. These have no bms and will simply damage themselves before they would not supply the amperage. The downside is any problem with the stator or short in wiring can be VERY bad. Overcharging lithium cells can cause them to burst and vent all kinds of horrible sometimes flammable substances. Ever see a lithium battery burn?

I am a huge advocate of lithium batteries but not in a powersports application.

My $0.02

.

.