Hi Everyone. I need a little expert help for my 1971 250 Cross. Any advice or guidance gratefully recieved.

The engine was rebuilt a while ago by someone who knows these engines ( ex MXer who ran Huskys in the UK ). Got new piston from Vintco and a few other parts I needed. I'm new to two strokes, and when I threw it back into the back and buttoned it up, I pick up the wrong can of fuel and ran it for about 5 minutes. Result was a badly scratched cylinder and a torn up piston with seized rings. My error. Not doing that again.

However, a year or so later ( my projects are slow ) I have the engine back in the bike. I had the cyclinder bored out and the next size up piston from Vintco. I fitted the new piston myself, and while it was the first time I've done that I was very careful. Everything checked out. Compression was great. Made sure I had the 2 stroke fuel made up ( temporary tank ) and fired it up. Within a few kicks, it fired right up. It ran for a few seconds and I hit the kill switch. Exhaust was not fitted correctly ( no springs ) so there was a little smoke but all looked fine. Happy boy.

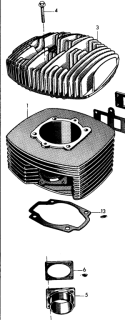

A week later, I'm back in the garage and have buttoned up a few more things. Rechecked torque on the head. Exhaust springs on. Quick compression check, and it's around 140. I have fuel ( again, very careful to check it's the correct mix 2 stroke ). Check for spark ( it's a new Vape ignition ) and I kick it over. It takes alot of kicking, but eventually fires up. Runs on its own for 5 seconds and then dies. Smoke coming out of the front of the engine and I'm wondering whether I've blown a gasket, but then remember the cylinder and the head have no gasket. Kicking it over now feels like there's no compression, so I do a check and it's below 50. Not good. Check the manual and it talks to lapping in the head and cylinder spigot as an initial run can find leaks in that mating, so I bought some lapping paste and take the head and cylinder off.

And there are scratches on the cylinder. The ring is seized in the piston. The piston above the ring feels like I've been hitting it with a screwdriver. It feels jagged when I run my hands over it. It's not as bad as the previous piston that I ran in the bike with no oil, but it doesn't feel like I want to put it back in the cylinder again and the ring is now seized in place, so is not sealing which is why I have no compression.

So I'm stumped as to what has happened and I've missed something fundamental. I've added some photos here and a video of the first run.

Video of first run here. Nothing untoward.

drive.google.com

drive.google.com

This was the first piston that I messed up and ran without two stroke fuel. See that pitting above the ring gap ? That looks like it's happening again.

drive.google.com

drive.google.com

The engine was rebuilt a while ago by someone who knows these engines ( ex MXer who ran Huskys in the UK ). Got new piston from Vintco and a few other parts I needed. I'm new to two strokes, and when I threw it back into the back and buttoned it up, I pick up the wrong can of fuel and ran it for about 5 minutes. Result was a badly scratched cylinder and a torn up piston with seized rings. My error. Not doing that again.

However, a year or so later ( my projects are slow ) I have the engine back in the bike. I had the cyclinder bored out and the next size up piston from Vintco. I fitted the new piston myself, and while it was the first time I've done that I was very careful. Everything checked out. Compression was great. Made sure I had the 2 stroke fuel made up ( temporary tank ) and fired it up. Within a few kicks, it fired right up. It ran for a few seconds and I hit the kill switch. Exhaust was not fitted correctly ( no springs ) so there was a little smoke but all looked fine. Happy boy.

A week later, I'm back in the garage and have buttoned up a few more things. Rechecked torque on the head. Exhaust springs on. Quick compression check, and it's around 140. I have fuel ( again, very careful to check it's the correct mix 2 stroke ). Check for spark ( it's a new Vape ignition ) and I kick it over. It takes alot of kicking, but eventually fires up. Runs on its own for 5 seconds and then dies. Smoke coming out of the front of the engine and I'm wondering whether I've blown a gasket, but then remember the cylinder and the head have no gasket. Kicking it over now feels like there's no compression, so I do a check and it's below 50. Not good. Check the manual and it talks to lapping in the head and cylinder spigot as an initial run can find leaks in that mating, so I bought some lapping paste and take the head and cylinder off.

And there are scratches on the cylinder. The ring is seized in the piston. The piston above the ring feels like I've been hitting it with a screwdriver. It feels jagged when I run my hands over it. It's not as bad as the previous piston that I ran in the bike with no oil, but it doesn't feel like I want to put it back in the cylinder again and the ring is now seized in place, so is not sealing which is why I have no compression.

So I'm stumped as to what has happened and I've missed something fundamental. I've added some photos here and a video of the first run.

Video of first run here. Nothing untoward.

IMG_6726.mov

drive.google.com

drive.google.com

This was the first piston that I messed up and ran without two stroke fuel. See that pitting above the ring gap ? That looks like it's happening again.

IMG_6812.JPG

drive.google.com

drive.google.com