SnoDrtRider

Husqvarna

A Class

Question... The chain rub guard on the swing arm... Does the long flap belong on the top or bottom of the arm?

As you all know, Coffee (Dean) passed away a couple of years ago. I am Dean's ex-wife's husband and happen to have spent my career in tech. Over the years, I occasionally helped Dean with various tech issues.

When he passed, I worked with his kids to gather the necessary credentials to keep this site running. Since then (and for however long they worked with Coffee), Woodschick and Dirtdame have been maintaining the site and covering the costs. Without their hard work and financial support, CafeHusky would have been lost.

Over the past couple of weeks, I’ve been working to migrate the site to a free cloud compute instance so that Woodschick and Dirtdame no longer have to fund it. At the same time, I’ve updated the site to a current version of XenForo (the discussion software it runs on). The previous version was outdated and no longer supported.

Unfortunately, the new software version doesn’t support importing the old site’s styles, so for now, you’ll see the XenForo default style. This may change over time.

Coffee didn’t document the work he did on the site, so I’ve been digging through the old setup to understand how everything was running. There may still be things I’ve missed. One known issue is that email functionality is not yet working on the new site, but I hope to resolve this over time.

Thanks for your patience and support!

Here's one , does this look like your's ?

View attachment 76771

have we got a clue what that other mounting tab is for

What colors did your guy use for the silver and gold? I'm about to have some more pieces powdered.

It's shown in the '81 parts book. P/n. 15 18 220-01

View attachment 76823

And in the '80 Auto supplement.. But then the swing has no tab for it instead!

View attachment 76824

The Silver is "Silver Anodize" with clear coat.

The gold I am not sure but I can check. It was some powder he had "Laying around" that he bought and did not like the color... I think it is perfect.

I believe your right on the left shock hose going that way the air box stone baffle is knotched out for that hose in that area.

On the chamber upper bolt with bracket do you have the spring on the bolt on the pipe? This absorbs the pipe vibration so the cracks intime won't happen. I can't see it in the pic. Sorry went back a page. And seen the spring.

That bike is the best looking 390 I've ever seen. So purdy.

Haven't up[dated for a few days... other projects...

I have been obsessing about the location of the left shock remote reservoir in front of the air box between the kick lever and the carb... Not liking the location.

I turned the top of the shock so the hose faces rearwards like the right side and found a location under the seat I am happy with. It will require re-working the stock mud guard or fabbing a complete new one but it is a much better location IMO.

Cable ties are just for trial location.

I was also not happy about clamping bare hose clamps down on my freshly powder coated frame so I came up with this... Slide a piece of 1/2" heat shrink tube over the clamp to isolate it from the frame... Clamps I had were too large in diameter but this will work!

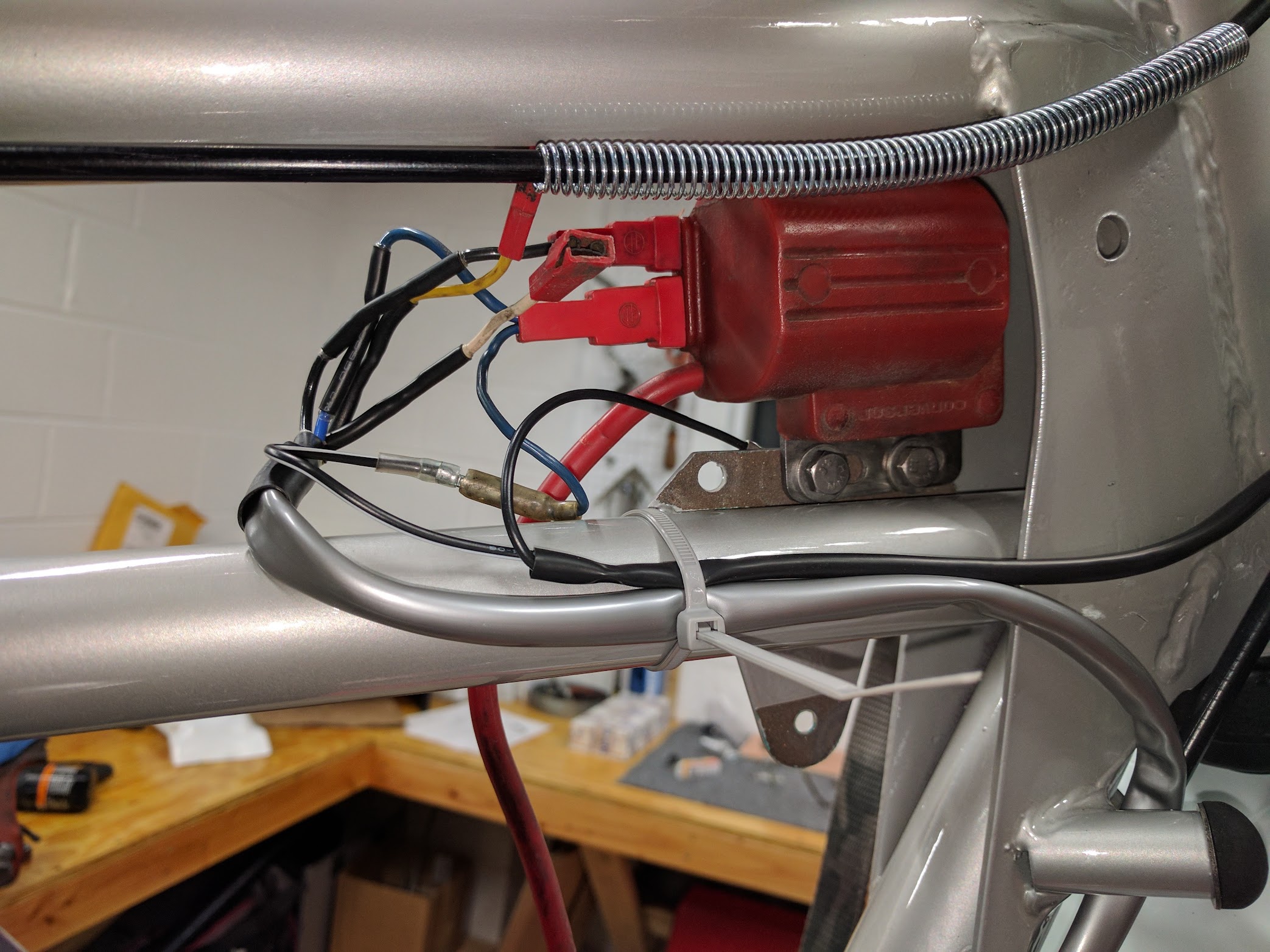

I also spent some time tidying up the wiring and cable routing...

I checked continuity of the ground circuit from the engine to the coil and the kill switch and came up good but I am still going to run an extra ground cable from the reed block to the coil. I ordered a roll of 1/4" x 25' braided copper bonding cable from Amazon today to make up a nice cable.

Note how my powder coater did exactly as I asked and masked off the coil and voltage regulator brackets after blasting and before coating... Can't say enough good about this guy!

silicone those wires to the coil and why are you running a ground wire to the reed block that seems really weird to me most guys just run a little short piece from the stator through the grommet to a motor mount

Aren't you still running steel bolt to mag cylinder/intake? I'm no expert on electrolysis, but if I were picking where to have it occur, I'd rather have it in a spot (engine mount) where corrosion doesn't have potential to impact the air seal on the intake. Also, Aluminum (if you're using the stock mount) is between Steel and Magnesium on the Galvanic series (granted those bolts holding the aluminum plates on the front of the engine are steel anyway).Stator has a verified good ground to the engine... engine to coil is what I am concerned with.

The only place the ground connection will likely change is at the motor mounts due to corrosion caused by electrolysis due to the dissimilar metals (Magnesium, Aluminum and Steel) all in the same area and possibly exposed to moisture. Stator is pretty much water tight so good contact there is not likely to change as it will at the mounts themselves.