FabOneUp

Husqvarna

Pro Class

Not a thread jack at all msmith345...this is exactly what we are about here! Anything you fab or have questions about fabrication go here, so your right on track.Ok, I'm at the point where I've got some projects I'd like to get going on, going to see if I can't add to this thread shortly with a top rack.

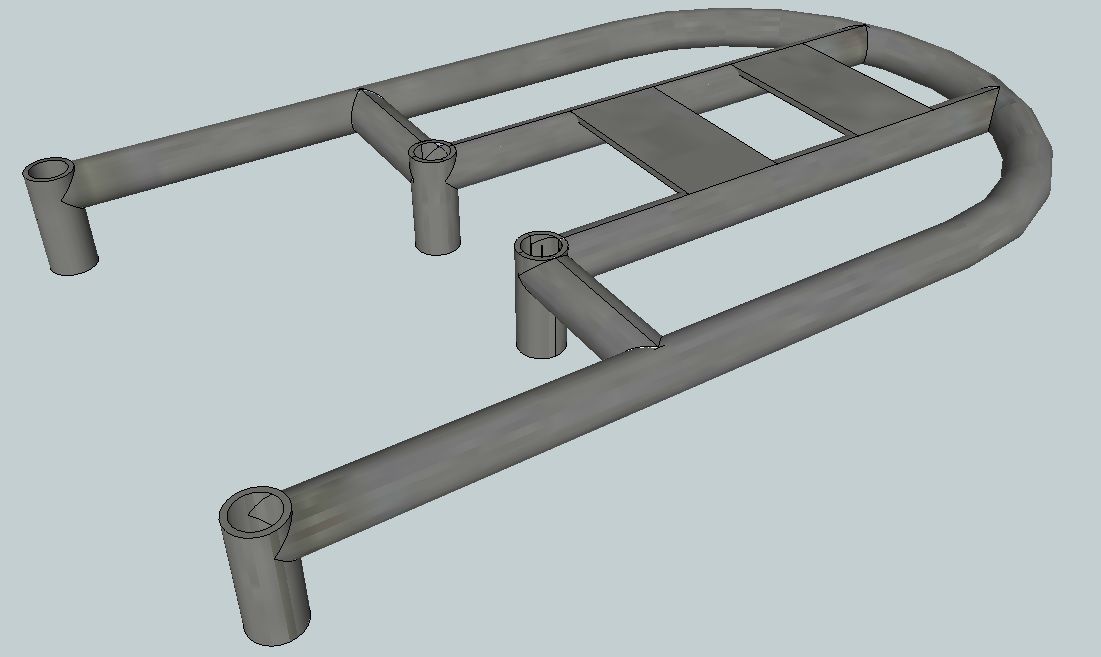

This is still related to terraformers, so don't take it as a thread jack. What I'm looking at doing for the top rack is using some 1/2" steel tube. Bending and welding it to give a strong base. Using probably some 1/8 solid round to bend into tie points. Then either making my own aluminum or HDPE plate for it, or picking up something that looks reasonable and bolting it to the frame. I'd like to go with probably a smaller pelican style case up there for commuting (most of the time), but I want to build it functional enough to handle week long camping trips.

For the side racks, I'll either make my own from the br-moto parts, or buy the pre-made one. I like the style of it and the price is good, so I'll likely just buy it pre-fabbed and call it good.

With that in mind, there are a couple tools I'll need to pick up:

**To minimize the thread jack, if you've got any recommendations, PM me and I'll just update this post with any recommendations for a terraformer starter setup.

- Bender - I was thinking this http://www.harborfreight.com/bench-top-bar-and-rod-bender-38471.html

- Welder - I have access to a MIG I've used quite a bit at my dad's house, but I'd like to get set up in my own shop a bit. I don't have a 230v access in my garage, so I'm looking for a 115v arc (possibly with tig option) setup. Yeah, it's not the best setup, but I can't think of a time I've needed to weld thicker than what one of these can handle. There are several of these out there, and there is a wide range of price (and quality, I assume). HF has an 80 amp inverter arc ($150), Northern tool has their st80i arc ($180) with a tig option for $80 extra, and there is the Thermal Arc 95s stick/tig setup that runs around $450, but includes some needed extras as well.

I don't know much about that bender from HF, but I would guess if it truly does bend, it doesn't bend well or consistent. You are most welcome to prove me wrong. May I suggest that instead of buying the berg racks and HF bender, you buy this with a 3/4" die with a 3" radius: http://www.jd2.com/p-32-model-3-bender.aspx Use this to build your top and side racks all out of 3/4" DOM. The total cost will be within $75 of what you were already going to spend and you will have a lifetime tool with endless possibilities and professional results that can even make you money if need be someday. But I understand it also requires time you may not have and the pre made Berg racks are the fastest way to get you adventuring. You choose.

Welders: if you buy a cheap welder, just make sure it has a cooling fan. Otherwise it is only going to give you about a few miniutes of weld time before it trips a breaker. If you want middle of the road but very good, try for a used Lincoln, Hobart, HTP, or Miller mig that will run on your 115v house current. I bought a Lincoln Weldpak 100 for $100 a few years ago. I would think used welders are all over in Kansas, but I don't know. Spend as much money as you can on the welder....do what you will with your bender, but don't skimp on the welder. Look for duty cycles in percentage. The higher the number, the better. 100% duty cycle is an industrial grade welder while 30% duty cycle is about what the average person welding at home needs. Anything less is still useful, but not recommended by me.

. I don't think I would look at the Thermal Arc 95s only for reasons you already mention...the extras. You really have to fully commit to a tig welder, including practice time with a huge learning curve. I don't think I will ever perfect TIG welding to my satisfaction, but I was MIG welding at a near professional level in a very short time at a very young age. MIG is faster, easier, and cheaper. In a perfect world, the ultimate welder for you is a Snap-On 140a. It runs on 115v, has 100% duty cycle and come up used all the time for under a grand.

. I don't think I would look at the Thermal Arc 95s only for reasons you already mention...the extras. You really have to fully commit to a tig welder, including practice time with a huge learning curve. I don't think I will ever perfect TIG welding to my satisfaction, but I was MIG welding at a near professional level in a very short time at a very young age. MIG is faster, easier, and cheaper. In a perfect world, the ultimate welder for you is a Snap-On 140a. It runs on 115v, has 100% duty cycle and come up used all the time for under a grand.Take this all lightly. Do what works for you and let us know the details and what you created. If it isn't Husky related, just make sure we can see a bike in the background.