Learned something new about the bike which anyone else thinking about strapping luggage like the Giant Loop bags on might like to know.

I went away for the weekend. 350km trip away and another 350km back. After the trip out, the bag worked great. Halfway home on the return leg I found that the heat shield on the left side had melted into the exhaust pipe.

I figured it wasn't going to get any worse, gave the bag a minor adjustment on that side, and headed home.

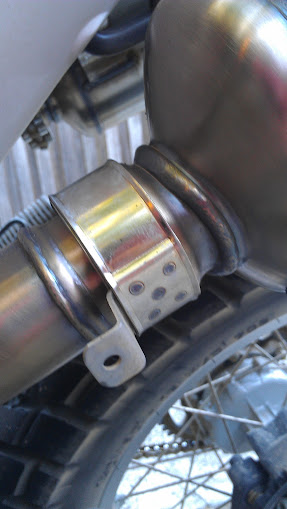

The heat shields on the exhaust are held on by two torx screws at the top, and a rubber stopper at the front, on the side, to hold the heat shield away from the pipe.

Here's the cause. The rubber stopper has gone missing. This allowed the shield to bend more than usual and hit the pipe and melt. Looks like an alternative solution to the rubber stopper is required here.