Big Timmy

Husqvarna

Pro Class

My bike has the same damage, it was repaired with jb weld, has held up good so far.

blueknob,

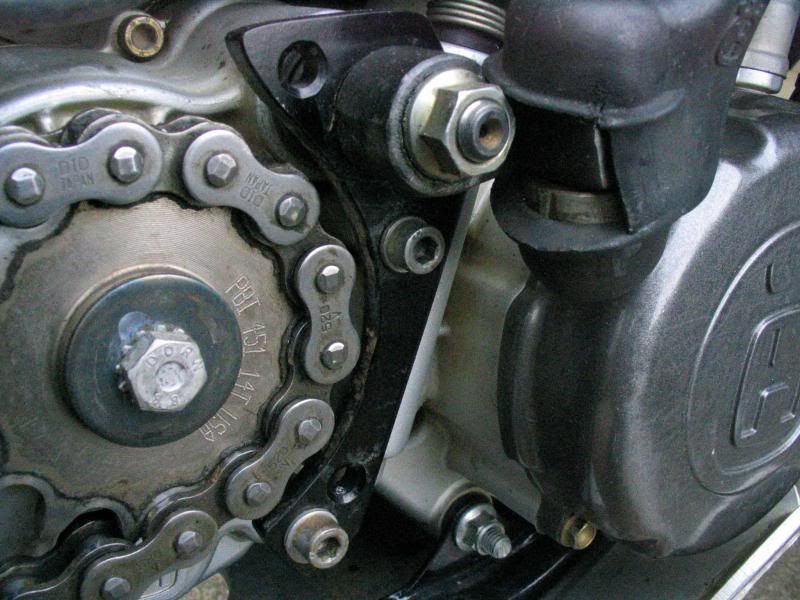

I have to ask what kind of chain is that? It has straight inner links with a profiled hole and the outer links are regular shaped. Kind of different? Never seen one like that.

I'm Cool with the JB weld if thats what you all like. Its a bandaid fix no matter how you look at the product. I carry some in my tool bag myself for emergency repairs, some stick epoxy also. It's an old habit I can't seem to break. Go for it with the JB and then ride it if you like, just clean it up good first and rough up any smooth surfaces so it has a bit of "tooth" and it will stick like S$%t on a baby blanket. I know because I have had to get it off hundreds of times to actually weld cases up myself.. If you ever dissasemble it then weld it. Thats just me but I've had a Tig welder in my shop since 1978 to do that sort of thing. Others at work everyplace I have been employed since the 70's as well. So its just what I would do and thats do a proper undetectable repair, it can be done.

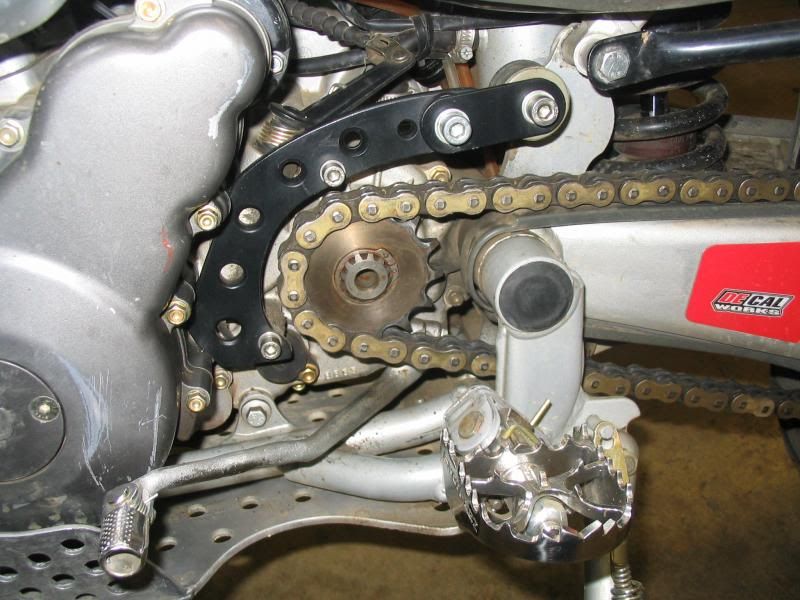

. Would love to see the state of your linkage and swingarm bearings after that beach escapade. That mount is only designed to hold a plastic cover so no design issue imo. Many actually take that guard off but i have fitted a chain guard behind it (with a bit of modification).

. Would love to see the state of your linkage and swingarm bearings after that beach escapade. That mount is only designed to hold a plastic cover so no design issue imo. Many actually take that guard off but i have fitted a chain guard behind it (with a bit of modification).