Using Tinkens idea of a standard silencer....another trick is to add a longer tube to the baffle and then drill a couple holes crossways in it. This will tend to soften sound a bit. I did this to the Leo on 610 using a couple inches of metal fencing pipe and rivets.

-

Hi everyone,

As you all know, Coffee (Dean) passed away a couple of years ago. I am Dean's ex-wife's husband and happen to have spent my career in tech. Over the years, I occasionally helped Dean with various tech issues.

When he passed, I worked with his kids to gather the necessary credentials to keep this site running. Since then (and for however long they worked with Coffee), Woodschick and Dirtdame have been maintaining the site and covering the costs. Without their hard work and financial support, CafeHusky would have been lost.

Over the past couple of weeks, I’ve been working to migrate the site to a free cloud compute instance so that Woodschick and Dirtdame no longer have to fund it. At the same time, I’ve updated the site to a current version of XenForo (the discussion software it runs on). The previous version was outdated and no longer supported.

Unfortunately, the new software version doesn’t support importing the old site’s styles, so for now, you’ll see the XenForo default style. This may change over time.

Coffee didn’t document the work he did on the site, so I’ve been digging through the old setup to understand how everything was running. There may still be things I’ve missed. One known issue is that email functionality is not yet working on the new site, but I hope to resolve this over time.

Thanks for your patience and support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Decatting the TE511 Muffler...

- Thread starter Motosportz

- Start date

Tinken

Husqvarna

Pro Class

The Q4 is quieter because it has a baffle welded inside and they charge you $100 more for this.

This adds considerable back pressure. Alternatively you can add baffles that merely redirect the sound into the outer sound packing without adding the back pressure.

Even the insert can have a baffle added to reflect sound backward into the packing and not the exhaust exit.

No turn key options here unfortunately, but I did manage to scrounge up a project listed below if you were interested...

A crude drawing of added baffles, image A on top is a straight through baffle. Image B has baffles added to redirect the sound waves into the exhaust packing which quiets the exhaust without adding too much back pressure.

What You'll Need

1- Cutting tool to cut slots in your baffles, die grinder works

4- Fender Washers to insert and weld into the slots

Welding unit or torch (friend or shop if you don't have one) to tack the washers in place so they don't rattle

How To Do It

1. Take the baffle out of the pipe and remove the fiberglass packing.

2. With a hacksaw, die grider wheel, or chop saw cut 4 slices not quite half waythrough the baffle.

With a hacksaw, die grider wheel, or chop saw cut 4 slices not quite half waythrough the baffle.

3. Find a couple fender washers that are the same diameter as the baffle pipe. You could just cut them in half or the line just above the hole in the center if extra baffle is needed.

Find a couple fender washers that are the same diameter as the baffle pipe. You could just cut them in half or the line just above the hole in the center if extra baffle is needed.

4. This is what I used to put into the baffle.

This is what I used to put into the baffle.

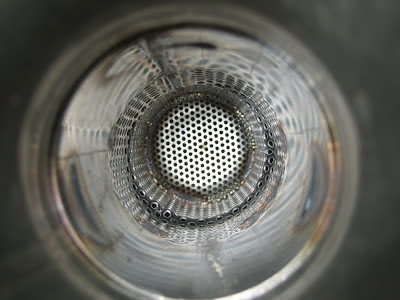

5. Here you see one washer in the pipe.

Here you see one washer in the pipe.

6. Here are two washers.. and so on. Note: I would add baffles with such size to where you could not see directly down the middle of the tube like those shown in this picture. This would assure that the sound waves were being redirected completely and not straight out the pipe.

Here are two washers.. and so on. Note: I would add baffles with such size to where you could not see directly down the middle of the tube like those shown in this picture. This would assure that the sound waves were being redirected completely and not straight out the pipe.

7. I split the pipe in half so you can see how the split washers will look inside the pipe. Weld them into place and if you feel like it grind off any burrs that are left, although it’s not necessary. Repack the fiberglass or if it’sbad then replace the packing. Reinstall the baffles and fire it up!

I split the pipe in half so you can see how the split washers will look inside the pipe. Weld them into place and if you feel like it grind off any burrs that are left, although it’s not necessary. Repack the fiberglass or if it’sbad then replace the packing. Reinstall the baffles and fire it up!

An alternative method I would use is to v-notch the washers and then place them 180° apart so that there were no line of sight for the exhaust to flow through. The more of these you had, the lower the dB output you would have. Remember to leave room for your insert at the end.

This adds considerable back pressure. Alternatively you can add baffles that merely redirect the sound into the outer sound packing without adding the back pressure.

Even the insert can have a baffle added to reflect sound backward into the packing and not the exhaust exit.

No turn key options here unfortunately, but I did manage to scrounge up a project listed below if you were interested...

A crude drawing of added baffles, image A on top is a straight through baffle. Image B has baffles added to redirect the sound waves into the exhaust packing which quiets the exhaust without adding too much back pressure.

What You'll Need

1- Cutting tool to cut slots in your baffles, die grinder works

4- Fender Washers to insert and weld into the slots

Welding unit or torch (friend or shop if you don't have one) to tack the washers in place so they don't rattle

How To Do It

1. Take the baffle out of the pipe and remove the fiberglass packing.

2.

With a hacksaw, die grider wheel, or chop saw cut 4 slices not quite half waythrough the baffle.

With a hacksaw, die grider wheel, or chop saw cut 4 slices not quite half waythrough the baffle. 3.

Find a couple fender washers that are the same diameter as the baffle pipe. You could just cut them in half or the line just above the hole in the center if extra baffle is needed.

Find a couple fender washers that are the same diameter as the baffle pipe. You could just cut them in half or the line just above the hole in the center if extra baffle is needed. 4.

This is what I used to put into the baffle.

This is what I used to put into the baffle.5.

Here you see one washer in the pipe.

Here you see one washer in the pipe.6.

Here are two washers.. and so on. Note: I would add baffles with such size to where you could not see directly down the middle of the tube like those shown in this picture. This would assure that the sound waves were being redirected completely and not straight out the pipe.

Here are two washers.. and so on. Note: I would add baffles with such size to where you could not see directly down the middle of the tube like those shown in this picture. This would assure that the sound waves were being redirected completely and not straight out the pipe.7.

I split the pipe in half so you can see how the split washers will look inside the pipe. Weld them into place and if you feel like it grind off any burrs that are left, although it’s not necessary. Repack the fiberglass or if it’sbad then replace the packing. Reinstall the baffles and fire it up!

I split the pipe in half so you can see how the split washers will look inside the pipe. Weld them into place and if you feel like it grind off any burrs that are left, although it’s not necessary. Repack the fiberglass or if it’sbad then replace the packing. Reinstall the baffles and fire it up!An alternative method I would use is to v-notch the washers and then place them 180° apart so that there were no line of sight for the exhaust to flow through. The more of these you had, the lower the dB output you would have. Remember to leave room for your insert at the end.

The Barrett I run has a huge through hole but a perforated diffuser at the end of it. Dont know how it stacks up power wise but my bike is pretty fast / powerful and is also very nice sounding and far from loud. My buddies stock KTM350 is a good bit louder.

bigmo

Husqvarna

AA Class

Ok, for those sitting on the sidelines. This is NOT that bad. It actually took me almost as long to get the rivets out as getting the cat out.

Here is what it looked like as I started:

And I had five welds holding the cat to the can:

My sawzall didn't do much, so I just got the grinder and went at it. I started grinding, then switched to a cutoff blade (I ate two total). Once the welds were gone, I just cut about 1/4" deep all the way around. As it got hot from the cutting, I could feel it getting loose.

I kept working around the whole canister and it progressively got looser. As I completed the circle it just fell out.

The end result was not too bad. I had a couple of rough spots to clean up, but was very pleased with the result.

Didn't get to take the bike for a ride, but I can already tell this is the ticket. A) You lose about 2 pounds of precious metals. B) The bike obviously can breathe WAY better - it already feels cooler just sitting their idling. I already ran map set 3, so my throttle response was excellent - but I can tell this will yield the benefits I was looking for.

Weight, temp, power, response - all in that stupid little donut from hell.

BTW, I could not really tell ANY increase in sound. I wish I would have done some baseline testing prior to cutting it out. My wife is an audiologist and has access to some excellent portable sound equipment. Doh...too late! There is sertainly a change in the tone, but the bike is still ridiculously quiet.

Thanks OP! I needed this!

Here is what it looked like as I started:

And I had five welds holding the cat to the can:

My sawzall didn't do much, so I just got the grinder and went at it. I started grinding, then switched to a cutoff blade (I ate two total). Once the welds were gone, I just cut about 1/4" deep all the way around. As it got hot from the cutting, I could feel it getting loose.

I kept working around the whole canister and it progressively got looser. As I completed the circle it just fell out.

The end result was not too bad. I had a couple of rough spots to clean up, but was very pleased with the result.

Didn't get to take the bike for a ride, but I can already tell this is the ticket. A) You lose about 2 pounds of precious metals. B) The bike obviously can breathe WAY better - it already feels cooler just sitting their idling. I already ran map set 3, so my throttle response was excellent - but I can tell this will yield the benefits I was looking for.

Weight, temp, power, response - all in that stupid little donut from hell.

BTW, I could not really tell ANY increase in sound. I wish I would have done some baseline testing prior to cutting it out. My wife is an audiologist and has access to some excellent portable sound equipment. Doh...too late! There is sertainly a change in the tone, but the bike is still ridiculously quiet.

Thanks OP! I needed this!

I think we should go into the muffler business Tinken.

Lets just make a titanium silencer with 2 cores, and outlets. Like the old 570 huskies had?

Top core is a typical glasspack straight in straight out. Bottom core is what you pictured. Have a screw on cap for the straight through core. Okay I want to be loud, let them both open....okay I want to be quiet, screw on the cap on the loud core. Cores could be smaller in diameter vs what we have now, and that would mean the quiet core would likely not require a ton of baffles or anything to restrict it too much. If aKRAPovic can make money selling 2000$ dirt bike exhausts, I think we could make as much at half the price. now to find perforated titanium tubing

Lets just make a titanium silencer with 2 cores, and outlets. Like the old 570 huskies had?

Top core is a typical glasspack straight in straight out. Bottom core is what you pictured. Have a screw on cap for the straight through core. Okay I want to be loud, let them both open....okay I want to be quiet, screw on the cap on the loud core. Cores could be smaller in diameter vs what we have now, and that would mean the quiet core would likely not require a ton of baffles or anything to restrict it too much. If aKRAPovic can make money selling 2000$ dirt bike exhausts, I think we could make as much at half the price. now to find perforated titanium tubing

JRW

Husqvarna

AA Class

Rode it yesterday... WOW Went into "race map II" mode on it's own

So with a decat or aftermarket pipe you can't switch between map 1 and 2 using the plug under the seat?

danny318

___________

I have a hard time believing this. Just use the jumperSo with a decat or aftermarket pipe you can't switch between map 1 and 2 using the plug under the seat?

JRW

Husqvarna

AA Class

I have a hard time believing this. Just use the jumper

I think I've read 2 different posts about this. Was just wondering if I lost the ability to use map 1 if I have an aftermarket pipe or decat mine.

domrvt

Husqvarna

AA Class

I think I've read 2 different posts about this. Was just wondering if I lost the ability to use map 1 if I have an aftermarket pipe or decat mine.

I think the issue is you'll be too lean with a slip on and Map 1.

Tinken

Husqvarna

Pro Class

I think we should go into the muffler business Tinken.

Lets just make a titanium silencer with 2 cores, and outlets. Like the old 570 huskies had?

Top core is a typical glasspack straight in straight out. Bottom core is what you pictured. Have a screw on cap for the straight through core. Okay I want to be loud, let them both open....okay I want to be quiet, screw on the cap on the loud core. Cores could be smaller in diameter vs what we have now, and that would mean the quiet core would likely not require a ton of baffles or anything to restrict it too much. If aKRAPovic can make money selling 2000$ dirt bike exhausts, I think we could make as much at half the price. now to find perforated titanium tubing

I met one of these dual outlet Yosh units doing sound check at the Funky Chicken...nice sound, quiet.

Tinken

Husqvarna

Pro Class

Yes, but they weight more than a WWII boat anchor. We have the new ProCircuit silencers and they are quiet and powerful while retaining the quality you would expect from an American made item (unlike F brand obviously).I met one of these dual outlet Yosh units doing sound check at the Funky Chicken...nice sound, quiet.

Yes, but they weight more than a WWII boat anchor. We have the new ProCircuit silencers and they are quiet and powerful while retaining the quality you would expect from an American made item (unlike F brand obviously).

Jake's FC450 was the quietest 4 stroke I tested, with the Yosh a close second, couple of new Yamahas were right in there with the stock pipe. Old KTM 200 with a properly packed hockey stick muffler is the gold standard...hard to get those things into the 90s.

that yosh is sexy.

Cosmokenney

Husqvarna

Pro Class

Old KTM 200 with a properly packed hockey stick muffler is the gold standard...

Since I'm running the F-brand PowerCore + Quiet Insert on my TE I'm very interested in what I can to to quiet her down a bit. I have read before that packing a silencer loosely will help, um, silence it. I have a roll of eBay stainless packing material sitting in my garage. I'd be open to suggestions on how to pack it properly to achieve a more subdued exhaust note.

I've noticed that at idle, the this exhaust is reasonable. But when you torque the throttle, the thing barks like a big dog. In a way it's cool, it sounds mean, but I'd hate to be the guy behind me.